Curved Glass Supplier | Innoglass Sdn Bhd

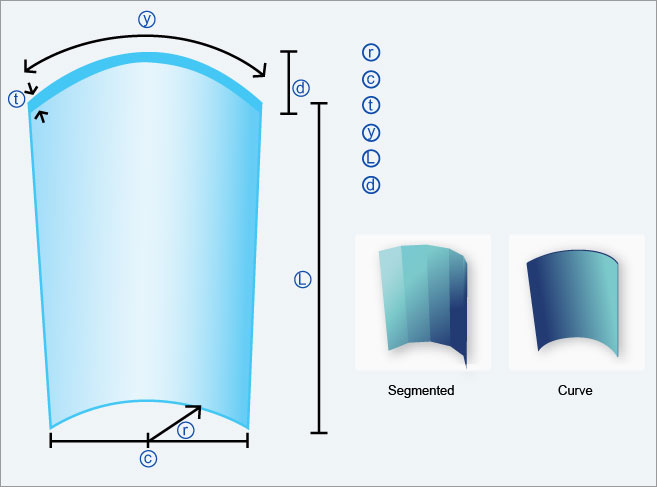

On the other hand, curve laminated glass required a set of stainless steel mould for each size and shape. The glass is put onto the mould and involves heating, then the glass will be softening and sag onto the mould by gravitational force and then it will send for lamination. Curve laminated glass offer less distortion compare to the curve tempered glass, and it can be form in multi directional and non-constant radius, like a 3D profiles where else curve tempered glass is restricted.

During the pass ten years curved glass has stimulated creativity, research, technical development and industrial specialization. Glass processors turn architects ideas into reality. Large curved glass surfaces are becoming an essential structural part of buildings, making close cooperation throughout the project essential. It would increase the aesthetic when a large curved glass instead of many segmented flat glass joining together to form a curvature.

Advantage of Using Tempered Glass

We are Here